Protective Eyewear Case

At Thrasio, the largest Amazon aggregator, I led a three week sprint to reimagine a protective eyewear case as a white space exploration. The concept was later selected to move into design for manufacturing and ultimately adopted into the Vaultz brand portfolio.

Company

Thrasio

Contribution

Design Lead

Design Research

CMF

User Experience

Product Visualization

Tools Used

Illustrator

Photoshop

SolidWorks

Keyshot

3D Printing

Current eyewear cases sit at two extremes: sporty rugged styles or delicate soft cases. Yet most people cycle through multiple pairs of eyewear over their lifetime, and few options offer both protection and a modern aesthetic. How might we innovate a case that balances durability with design to create something unique?

Next Steps – Prototyping & Testing

3D Printing: Produce initial case prototypes to evaluate form and fit.

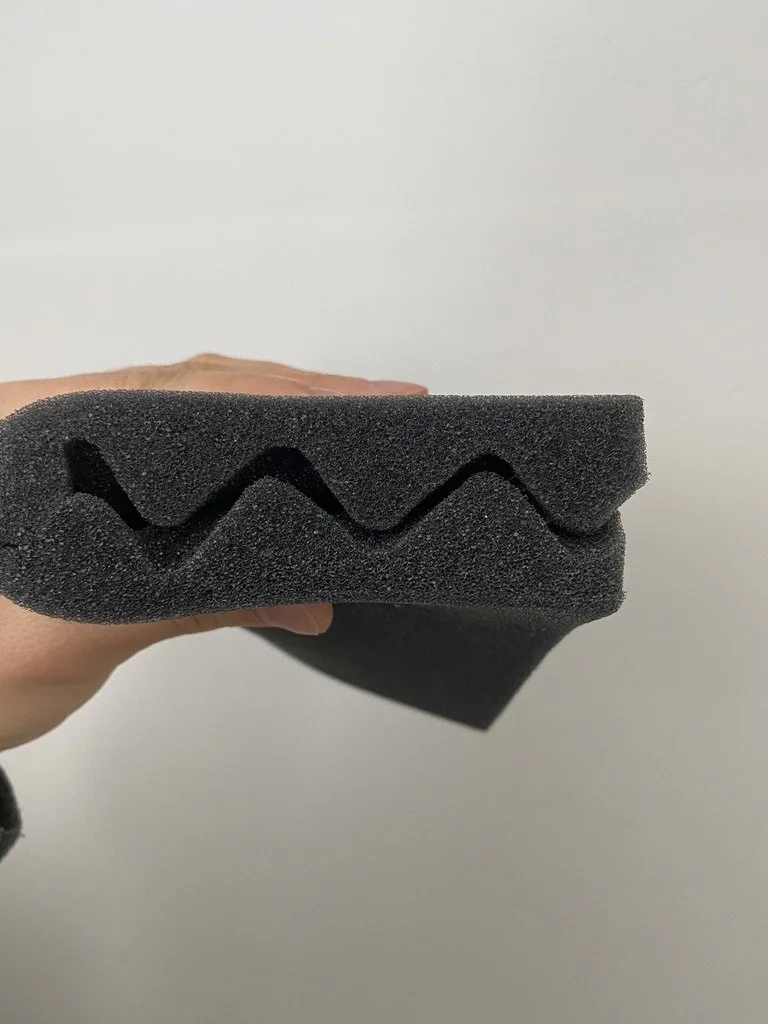

Foam: Source and test foams with varying densities and egg-crate patterns to optimize protection and fit.

Opening Mechanics:

Test spring resistance for desired open/close experience.

Add latch guard to prevent accidental opening.

Evaluate rotary damper combined with spring-loaded latch for smoother, controlled motion.

Interior: Prototype case lining and removable foam inserts sized for larger glasses.

Sealing & Durability: Integrate O-ring seal to assess water-resistance performance.